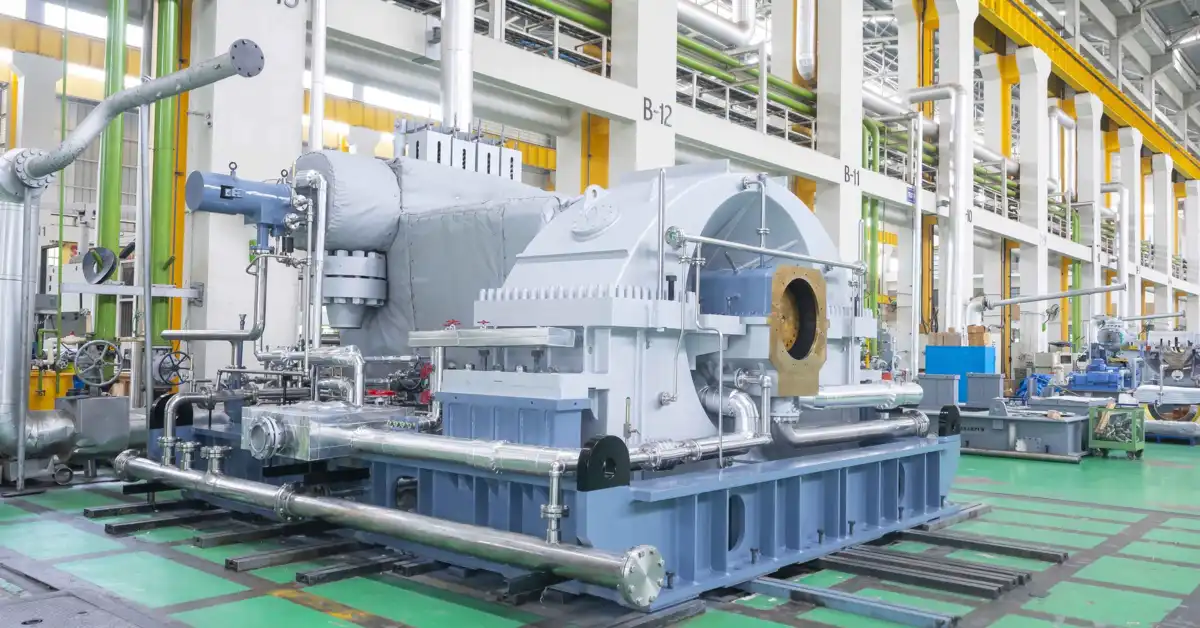

Industrial heating is one of the largest contributors to energy costs and emissions, making efficiency a critical priority. Traditional fuel-based systems struggle with rising expenses and sustainability concerns.

An industrial heat pump provides a smarter alternative, delivering higher efficiency, lower emissions, and reliable performance, helping industries reduce energy spend while supporting long-term environmental goals.

Why Industries Need Efficient Thermal Solutions

Industries like food processing, textiles, chemicals, and paper rely heavily on stable heating and cooling to sustain operations. Traditionally, this has been met using boilers and fossil fuels, but the costs are steep, including rising fuel expenses, frequent upkeep, and heavy emissions.

An industrial heat pump offers a smarter alternative. Powered by electricity, it transfers heat instead of generating it, delivering three to five times higher efficiency. This ensures more usable energy with lower costs and reduced environmental impact.

How CO₂ Becomes a Sustainable Refrigerant

One of the most promising advancements in the industrial heat pump technology is the adoption of Carbon Dioxide (CO₂) as a refrigerant. Unlike Hydrofluorocarbons (HFCs), which are being phased out due to high global warming potential, CO₂ delivers a minimal global warming potential of 1 and zero contribution to ozone depletion.

This preferred choice enables industries to not only meet evolving regulations but also lead the way in developing low-carbon, future-proof systems. By adopting CO₂-based heat pumps, businesses position themselves as leaders in energy efficiency and environmental responsibility.

Key Benefits of Adopting an Industrial Heat Pump

Industrial operations demand reliability, cost-effectiveness, and adaptability. Here are the top advantages companies see when they switch:

- Energy Savings: Industrial heat pumps are 3 to 5 times more efficient than fossil fuel-based systems, cutting energy bills dramatically.

- Lower Emissions: By running on electricity, especially from renewable sources, they reduce greenhouse gas emissions.

- Versatility: They deliver both heating and cooling in a single system, serving multiple processes simultaneously.

- Custom Solutions: Starting from 100 kW capacity, modern systems can be tailored to match unique temperature, pressure, and flow requirements.

- Regulatory Compliance: With sustainable refrigerants like CO₂, industries are safeguarded against future bans on harmful chemicals.

Industry Applications Driving Change

The adaptability of an industrial heat pump makes it suitable across diverse sectors:

- Food and Dairy Processing: Reliable heating and cooling cycles preserve product quality.

- Pulp and Paper: Stable thermal processes cut energy consumption in high-volume operations.

- Chemicals and Pharmaceuticals: Precision temperature control ensures safety and consistency.

- Textiles: Efficient heating supports dyeing and finishing processes.

- Breweries and Distilleries: Streamlined heating and cooling cycles optimize production.

- Marine and District Heating: Applications extend beyond factories to ships, submarines, and urban heating networks.

Future-proofing Industry with Innovation

Industrial heat pump design is advancing through partnerships between engineers and research institutions. Modern systems integrate seamlessly with existing setups, offering precise energy data and reliable performance.

These innovations cut downtime, lower maintenance, and accelerate ROI. As industries embrace electrification and renewables, industrial heat pumps emerge as key to efficiency, sustainability, and long-term business value.

Bring Efficiency and Sustainability Together

Today, thermal solutions are critical. Industrial heat pumps reduce energy costs, cut emissions, and ensure long-term operational resilience.

They provide industries with a clear path to electrification while strengthening climate commitments. When integrated with complementary technologies such as Steam turbines, these solutions unlock higher efficiency and reliability, enabling industries to transform energy use into measurable business value and future-ready performances.